WORKING WITH ECO PLASTICS

Jade Engineering develops bespoke cutting/welding for serial innovator.

Sean Preson is a serial inventor and innovator. The energetic head of Leicester-based Eco Plastic Wood Ltd is a committed environmentalist and through his firm offers a range of garden products, including benches, gates, sheds and other outbuildings, all manufactured using recycled plastics.

So when Sean decided to manufacture a range of outbuildings using fence panels manufactured using recycled, lead-free PVC-U that replicate tongue and grooved planks, welded together to produce larger sections for the buildings, he needed a fast, reliable solution for an application that simply did not exist.

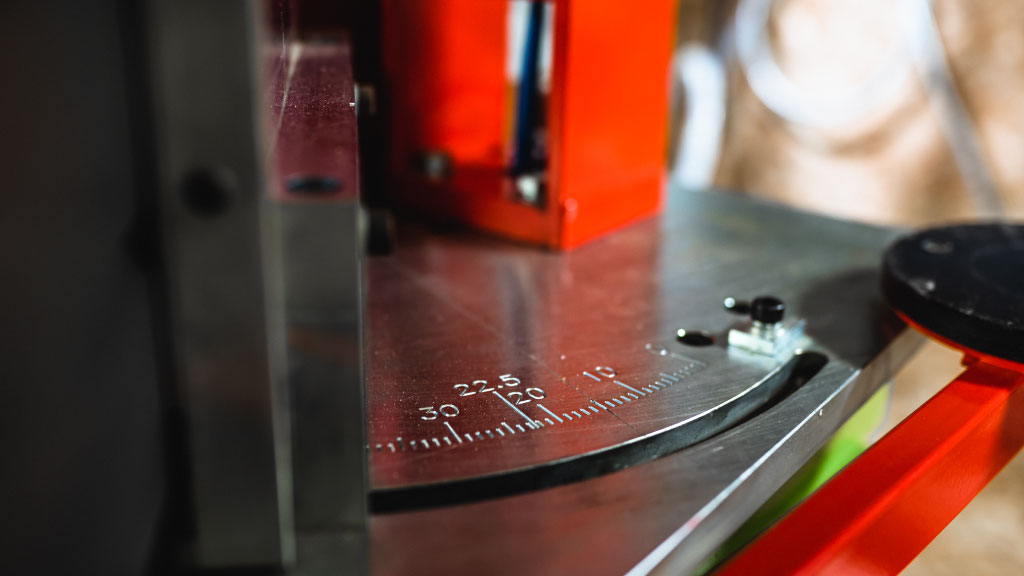

He called in Coventry-based Jade Engineering, with whom Sean had a previous relationship as suppliers of machine tools for Sean’s frame manufacturing business. He presented the challenge to them: “I had this idea of cutting then welding multiple fence panels together using existing V-notch saws, that could be combined together to cut left and right-hand mitres without having to re-position the panels each time,” explained Sean. “And then to present the panels together for welding into larger sections. But I needed someone with the expertise to make this work. And I knew that Jade Engineering liked a challenge,” added Sean mischievously.

After Sean fabricated a steel frame onto which the mitre saws were mounted, Jade designed and manufactured the clamps to secure the panels during cutting. The welding, however, required more significant input, explains Jade Engineering’s Adam Jones: “Initially we considered using a standard single head welder from our SALtech range. However, the size of the panels to be welded required a solution that was almost bespoke.”

Jade therefore developed and manufactured oversized clamps and heater plates to weld the combined panels together, with the SALtech welder heavily re-engineered to perform repeat welds, accurately and reliably. The result, says Sean Preson, works superbly: “Jade have done a superb job. They understood what I wanted to do, realised issues that would be encountered in executing such an unusual task and produced an ideal solution. It works perfectly, every time.”